FEASIBILITY STUDY

For GS4Plastic the feasibility study is a “must” and it has to respect the principles of lean thinking at every stage to optimize and reduce the cost of the finished product. The steps are the following:

Definition of the product’s features

Choice of the most suitable material and technology

Container and preform design

Estimation of the bottle’s weight

Estimation of the production’s cost

BOTTLES ENGINEERING

In over 22 years of experience, the team of GS4Plastic has developed many skills in the engineering of PET containers and bottles for various applications and it is now able to offer the following services:

Development of new design

Engineering of the container with a high optimization for a lightweighting results

Lightweighting projects on existing containers

Design of special containers (hot fill, with high grip handle or stackable bottles)

The engineering office of GS4Plastic is able to offer a complete design service, from the preform to the finished container, supporting the customer until the end of the prototyping process.

PREFORM ENGINEERING

GS4Plastic in addition to the study of the bottle can engineer the ideal preform with any type of neck and weight based on the chosen cap and the application of the container, respecting as much as possible the natural stretching ratios and the rheology of the various polymers, and optimizing the thicknesses in the important points of the preform. We carry out projects for preforms in PET, rPET, PEN, HDPE, PP, or other special polymers. GS4Plastic can therefore provide the engineering of preforms with any type of neck in different application areas:

CSD and beverage ( PCO 1881, Exalite, 29/25, 26/22)

Food (33/400, 38/400, Snap on 29/21 o 36/29, Corona, etc)

Detergent (24/410, 24/415, 28/410, 28/400, guala closure, etc)

Big mouth ( 53mm, 63 mm, 89 mm, )

Big containers ( PDC 55, Keg 78mm)

Specialties or New development (Aerosol, Pharma, etc)

Every project is guaranteed up to the prototyping and blow molding phase of container

PROTOTYPING

GS4Plastic within its own structure, in addition to the design, is also able to offer prototyping services for preforms and bottles in PET, rPET or PP or special compounds to offer a turnkey service from the idea to the final packaging for any type of application. Our assets are:

1 cavity blow molding machine up to 2L

Injection molding machine with Husky mold

Twin screw extruder for compounding tests

3D printer whit filament

3D printer whit pellet

Thermoforming laboratory machine

Dehumidifier

Grinder for the reuse and recovery of post-consumer plastic

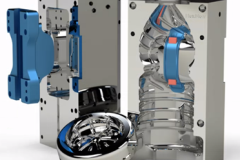

SUPPLY OF BLOW MOLD& BLOWING MACHINE

Strengthened by its expertise in the field of blowing and container production, GS4Plastic is able to select the best quality, production, price solution for supply of :

- molds and stretch-blow molding machines for containers in PET, rPET, PEN or PP or special polymers. The types of mould that we can offer are:

Mould for linear blow molding machines

Shell molds for rotary blow molding machines

Quick change conversion systems

Bottom modification systems

- the best technology and machine according with the request of the customers. The types of machine that we can offer are:

SBM machine (linear or rotary)

EBM machine for PE or PETG

ISBM machine for PET, HDPE PP

IBM machine for PET, HDPE PP