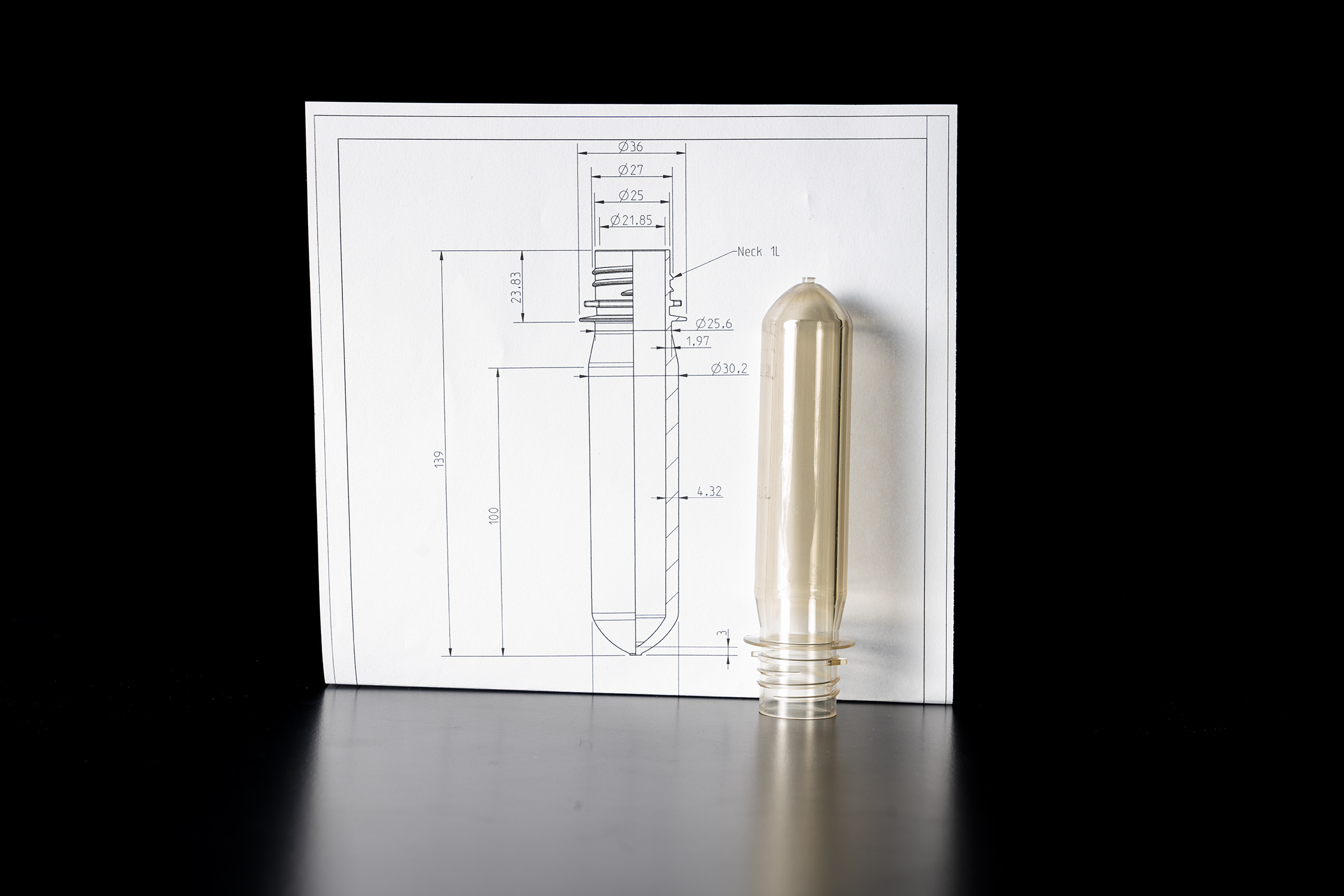

PREFORM ENGINEERING

GS4Plastic in addition to the study of the bottle can engineer the ideal preform with any type of neck and weight based on the chosen cap and the application of the container, respecting as much as possible the natural stretching ratios and the rheology of the various polymers, and optimizing the thicknesses in the important points of the preform.

We carry out projects for preforms in PET, rPET, PEN, HDPE, PP, or other special polymers. GS4Plastic can therefore provide the engineering of preforms with any type of neck in different application areas:

CSD and beverage ( PCO 1881, Exalite, 29/25, 26/22)

Food (33/400, 38/400, Snap on 29/21 o 36/29, Corona, etc)

Detergent (24/410, 24/415, 28/410, 28/400, guala closure, etc)

Big mouth ( 53mm, 63 mm, 89 mm, )

Big containers ( PDC 55, Keg 78mm)

Specialties or New development (Aerosol, Pharma, etc)

Every project is guaranteed up to the prototyping and blow molding phase of container